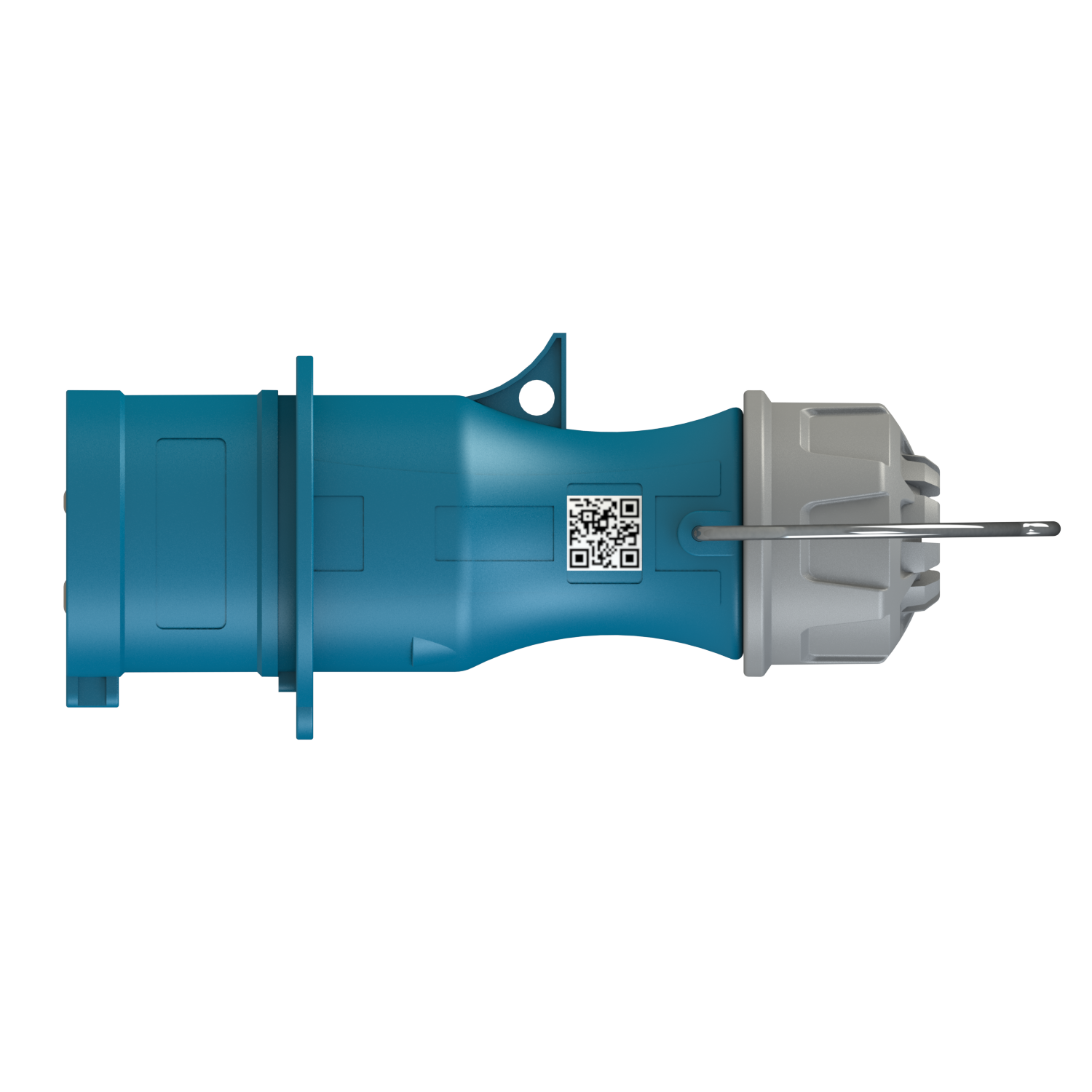

There are several special considerations to keep in mind when installing waterproof nylon cable connectors to ensure optimal performance and durability:

Proper Cable Preparation: Before installing the connector, ensure that the cable ends are correctly prepared. This includes stripping the insulation to expose the conductors and ensuring that the wires are clean and free from any damage or kinks.

Correct Connector Orientation: Pay attention to the orientation of the connector during installation. Make sure that the cable is properly aligned with the connector housing and that the cable gland or sealing mechanism is correctly positioned to provide effective waterproofing.

Tightening Torque: Use the manufacturer-recommended tightening torque when securing the cable gland or compression fitting. Over-tightening can damage the connector or compromise the integrity of the waterproof seal, while under-tightening may result in inadequate sealing and potential water ingress.

Sealing Compound: Consider using a sealing compound or lubricant recommended by the connector manufacturer to enhance the waterproofing performance and ensure a reliable seal. Apply the compound to the mating surfaces of the connector and cable gland to prevent moisture penetration.

Environmental Conditions: Take into account the environmental conditions in which the connector will be installed. Ensure that the connector is suitable for the specific application and that it can withstand exposure to moisture, humidity, temperature fluctuations, and other environmental factors.

Cable Strain Relief: Provide adequate strain relief for the cable to prevent tension or pulling forces from being transmitted directly to the connector. Use cable clamps, strain relief bushings, or other mechanical means to secure the cable and minimize stress on the connector.

Inspection and Testing: After installation, visually inspect the connector and surrounding area for any signs of damage, misalignment, or improper sealing. Perform electrical continuity and insulation resistance tests to verify the integrity of the connection and ensure that the waterproof seal is effective.

Regular Maintenance: Schedule periodic inspections and maintenance checks to monitor the condition of the connectors and ensure ongoing waterproofing performance. Replace any damaged or worn connectors promptly to prevent water ingress and maintain the reliability of the electrical connections.

By following these considerations and best practices, you can ensure the proper installation and effective waterproofing of nylon cable connectors, minimizing the risk of water ingress and ensuring reliable electrical connections in challenging environments.

Abroad:[email protected]

Domestic:[email protected]

Abroad:[email protected]

Domestic:[email protected]

Abroad: +86-18157471290

Domestic: +86-18157471293

Abroad: +86-18157471290

Domestic: +86-18157471293

- Home

- Products

- Industrial connectors

- Waterproof housings

- Power distribution box sets

- ABS electrical accessories

- Cables

- Moulds

- Power Distribution Board/Box

- Extension Lead with Plug

- AS/NZS Waterproof Electrical Products

- C Series IEC/CEE Waterproof Electrical Products

- B Series IEC/CEE Waterproof Electrical Products

- Waterproof Window Cover

- Waterproof Plastic/Metal/Aluminum Box

- House Use Electrical Items

- About Us

- FAQ

- News

- Contact Us